Nanopass 34G Pen Needle for insulin shots, with a gauge pared down to the absolute minimum level of thinness

Diabetes is becoming more widespread in children. The Nanopass resulted from deep concern for these children, as well as the tenaciousness exhibited by Terumo’s development team. It is a milestone achievement in the field of injection needles.

It took Terumo five grueling years to commercialize a needle that spares patients from the pain associated with injections.

When viewed by itself the

thi nness of the 34G (center)

is not that conspi cuous, but

it st ands out in co mparison

with t he 32G and 33G

An injection can be just as unpleasant for adults as it is for children. We put up with it out of necessity, but what if you needed injections on a daily basis? Diabetes patients deal with pain on a daily basis. They need to give themselves insulin shots one to four times a day, depending on their condition, to control their blood sugar level. And they have to do it 365 days a year. On top of the pain of the injection, habitual piercing takes a terrible toll on the skin.

To address this problem, the Japanese medical equipment corporation Terumo began developing a needle designed to cause less pain and skin scarring. Their first challenge was to design a 33G* needle with a diameter of only 0.2 mm at the tip, which could avoid hitting one of the 100-to-200 pain receptors per square centimeter of skin surface. Their solution was the Nanopass 33G.

Injection needles are typically manufactured by shaping a metal plate into a cylinder, then stretching it until it is very thin before cutting it into pieces. It may not sound very difficult to produce extremely thin needles, but the smaller the diameter of a needle, the higher the infusion resistance in the interior of the needle, which prevents the drug inside the needle from travelling properly toward the tip. Terumo’s development team found a solution known as a “double-tapered structure.” Both the exterior and interior diameters of a needle are gradually tapered off at the tip to facilitate the flow of insulin. Instead of using conventional manufacturing technology, Terumo opted for a revolutionary new production method where a metal plate is rolled up directly into an extremely thin tapered shape (lower right illustration).

The unprecedented shape of the proposed needle made it difficult for Terumo to locate a manufacturer capable of producing it. After approaching more than a hundred corporations and backstreet molding shops, it found Okano Kogyo, a company known for its superb mold and die technology. “Even for Mr. Okano, the challenge of creating the proposed needle was a difficult one,” recounted Takao Matsuo, a member of Terumo’s development team. It took three long years to create a finished product that satisfied everyone.

Further challenges

Three years had passed, and the goal seemed so near. The product was ready for manufacturing. Press machines capable of delicately pressing a small metal plate to gradually roll it into a cylinder with an exterior diameter of only 0.2 mm were built. A few additional steps, such as welding, attaching the edge and assembly, would in theory result in a finished injection needle ready for shipment.But the team encountered an unexpected problem. When the finished needles were bundled together, their tips tended to puncture each other’s bodies. The needle itself was ill-balanced, making it difficult to place the needles side by side. To process tens of thousands of needles efficiently, each needle would have to be properly handled and packaged.

It took an additional two years to set up a new manufacturing line to address the issue.

Like the edge of a Japanese sword

A developed view of th e

double-tapered struct ure

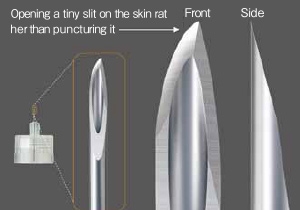

In addition to its extremely small tip diameter, the Nanopass has another special feature that helps to reduce pain. The edge of a conventional injection needle has symmetrical sides with a cone-shaped pointed end. This shape causes the infusion pressure exerted at the tip of a needle to concentrate on one point of the skin surface, causing the “pricking” sensation as the tip punctures the skin. The edge of the Nanopass needle is asymmetrical, almost like a Japanese sword. This edge comes into contact with the skin surface linearly and gently opens a tiny slit on the skin rather than puncturing it. The tip of the needle enters the skin with little resistance and without affecting the surrounding pain receptors.

In 2005 Terumo unveiled the Nanopass 33G, a pain-free insulin injection needle that was the thinnest in the world, followed by the even thinner Nanopass 34G in 2012. This needle, which has an external diameter of only 0.18 mm, has brought a lot of relief to patients with diabetes.

The Nanopass utilizes a double-tapered structure, i.e., the exterior and interior diameters of the needle are gradually tapered off at the tip.

The sword-like edge of the Nanopass. It opens a tiny linear slit, causing less pain and skin strain.