Technology to Purify Groundwater

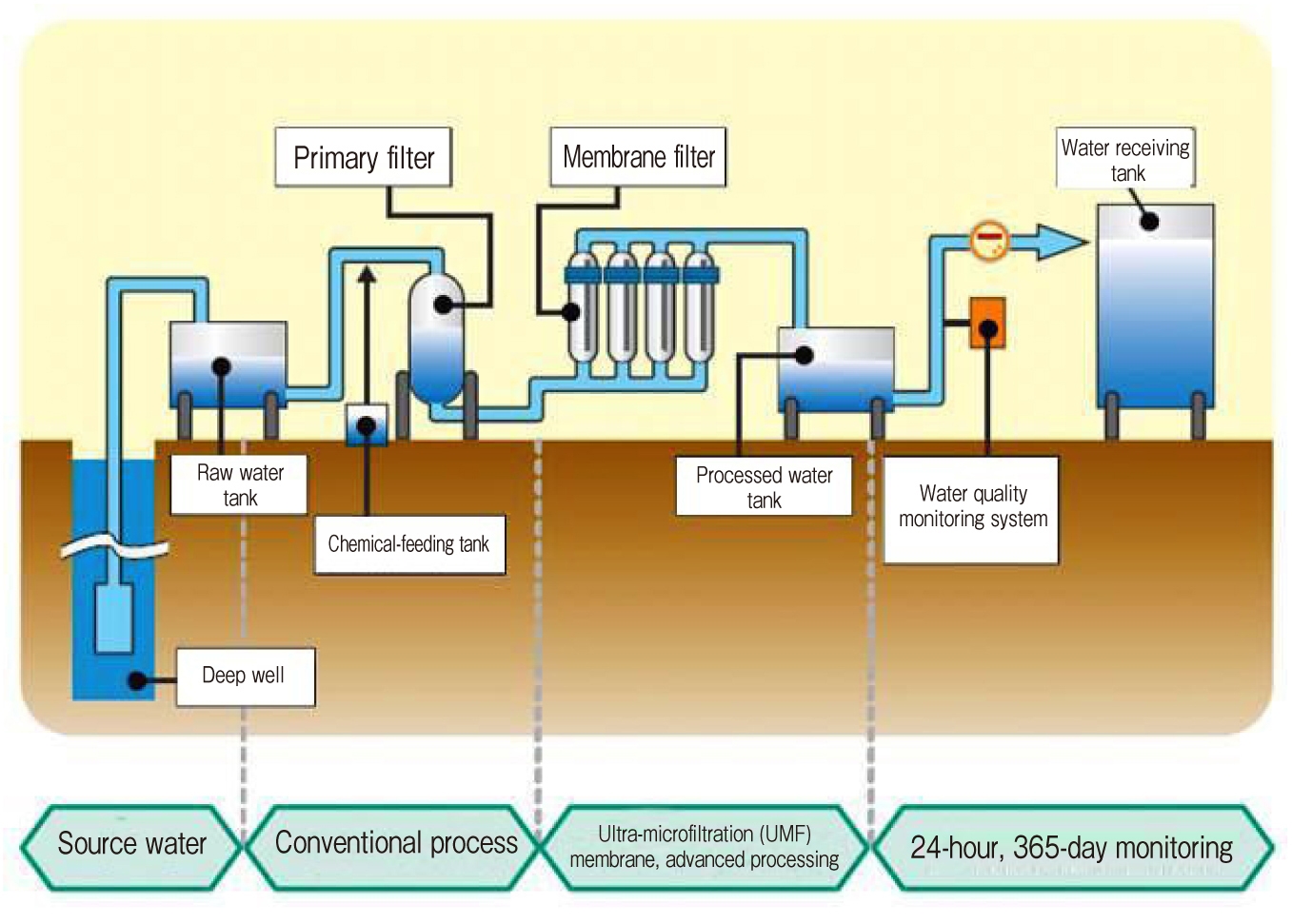

Cross section of the membrane, the nucleus of the membrane-filtration system. Each membrane is like a straw. The 0.01-wide pores on the surface of the membrane fiber filter the water that passes through.

When the lifelines of electricity, water, gas, telephones and other utilities are severed, electricity and telephones are usually restored comparatively quickly, but water and sewerage are the slowest to be restored. From the viewpoint of public hygiene, such as hand washing and bathing, more importance should be placed on everyone having their own water supply to maintain their lifestyle. “After the latest earthquake, I am convinced that we have been working in the right direction,” President Shoichi Fukuda proudly said. That’s only natural because there was little data, until now, to support the theory that groundwater is immune to earthquakes. The 1995 Great Hanshin Awaji Earthquake struck soon after Wellthy’s system was developed, so this is the first time the theory was substantiated.

This one-meter-long device

– the membrane – can process

1–2 tons of water per hour.

Installation has multiple merits

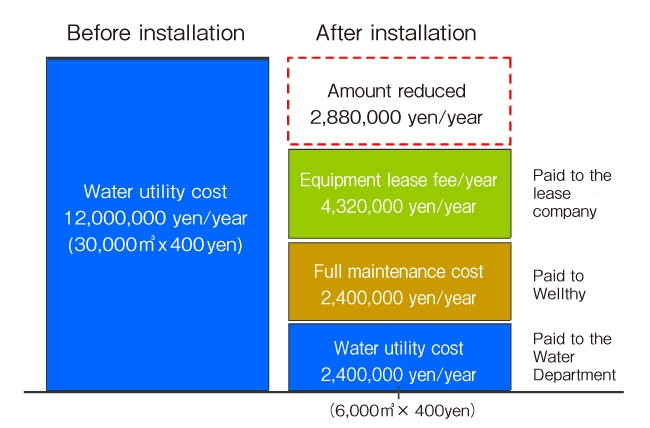

This system has many other advantages, such as cost reduction. Compared to using only the public water supply, companies can budget for a significant reduction in costs per year, even when including installation and maintenance costs.

When working with local communities and neighborhood associations, drinking water can be supplied to neighboring residents in times of disaster. By ensuring the availability of safe water at all times, companies contribute to the region and also improve their image.

Fukuda dived into the water business 15 years ago. Before that, his company was doing well manufacturing and selling electricity-saving equipment. One day, a client commented while signing the contract on the completion of fitting work, “With this, we are saving electricity. Is there any way to save gas and water?” Within days, Fukuda heard the same comment from other customers, so he searched the library to see if it was possible. He found that only the government was involved in supplying water with no competition.

“The field of electrics in which I was involved was highly competitive. Technology was evolving fast and constantly being honed. But one book mentioned that water technology had not advanced for 30 to 50 years due to a lack of competitors.” Fukuda said.

Groundwater pumped from a deep well is filtered through sand and activated charcoal and then filtered using the advanced ultrafiltration (UF)-membrane process. The membrane also completely removes bacteria and parasites. The safety equipment monitors the process 24 hours a day, all year round.